Double Sided Lighted Signs

Fabrication:______________________________________________________

Through experience with double-sided lighted signs, we have determined that fabricating the structure from scratch, rather than using pre-made kits from Excellart, yields superior results. While this approach involves additional steps and demands a higher level of skill, it ultimately produces a more refined and durable final product.

Step 1:

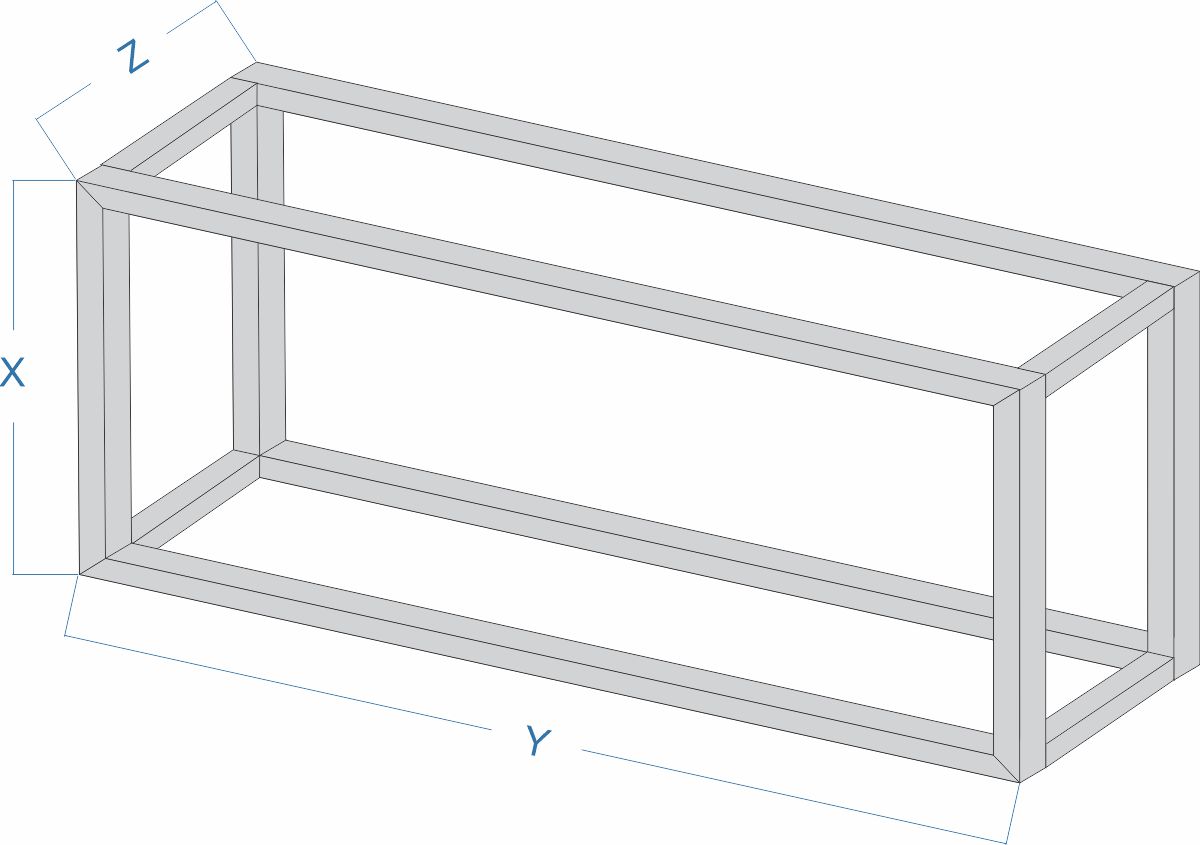

Using 2×2” steel tubing, construct a structural frame similar to the image below, adhering to the specific dimensions required for your project. For example, if the sign dimensions are 48”x96”, these represent the outer dimensions (OD) of the frame: X = 48” (vertical dimension), Y = 96” (horizontal dimension), and Z = the desired depth (thickness). Ensure that 45° mitered cuts are made at the corners for both the front and back sides, while straight 90° cuts should be used for the depth.

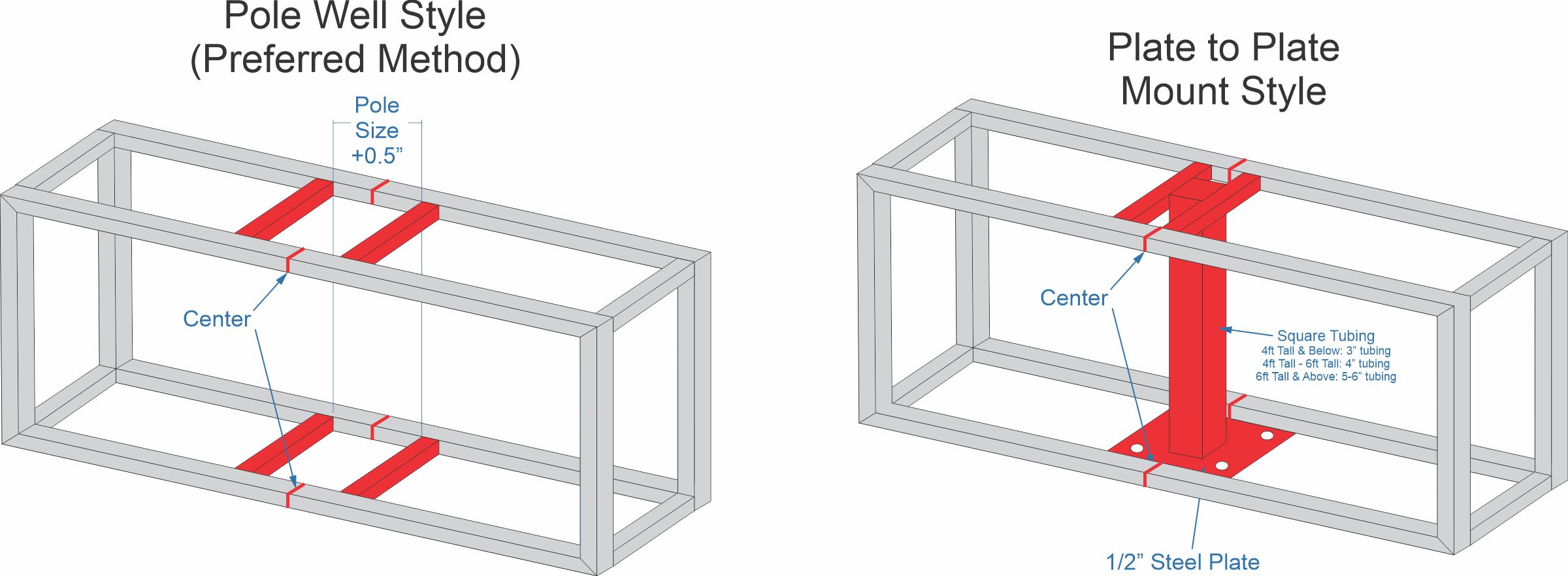

Using 2×2” square tubing, install four cross pieces for mounting to the pole at a later stage. Position these cross pieces on either side of the center at both the top and bottom of the sign. Ensure they are mounted with a spacing equal to the width of the pole plus a minimum additional ½”. See Below

Step 2B:

For a plate-to-plate style mount, an upright post, typically 3-4” square tubing, is required, along with 2×2” tubing to weld to the top center. A ½” steel plate with four mounting holes is also necessary, with the holes sized sufficiently to accommodate the mounting bolts. Additionally, an identical plate with matching holes must be fabricated and welded to the top of the installed ground pole. See Below:

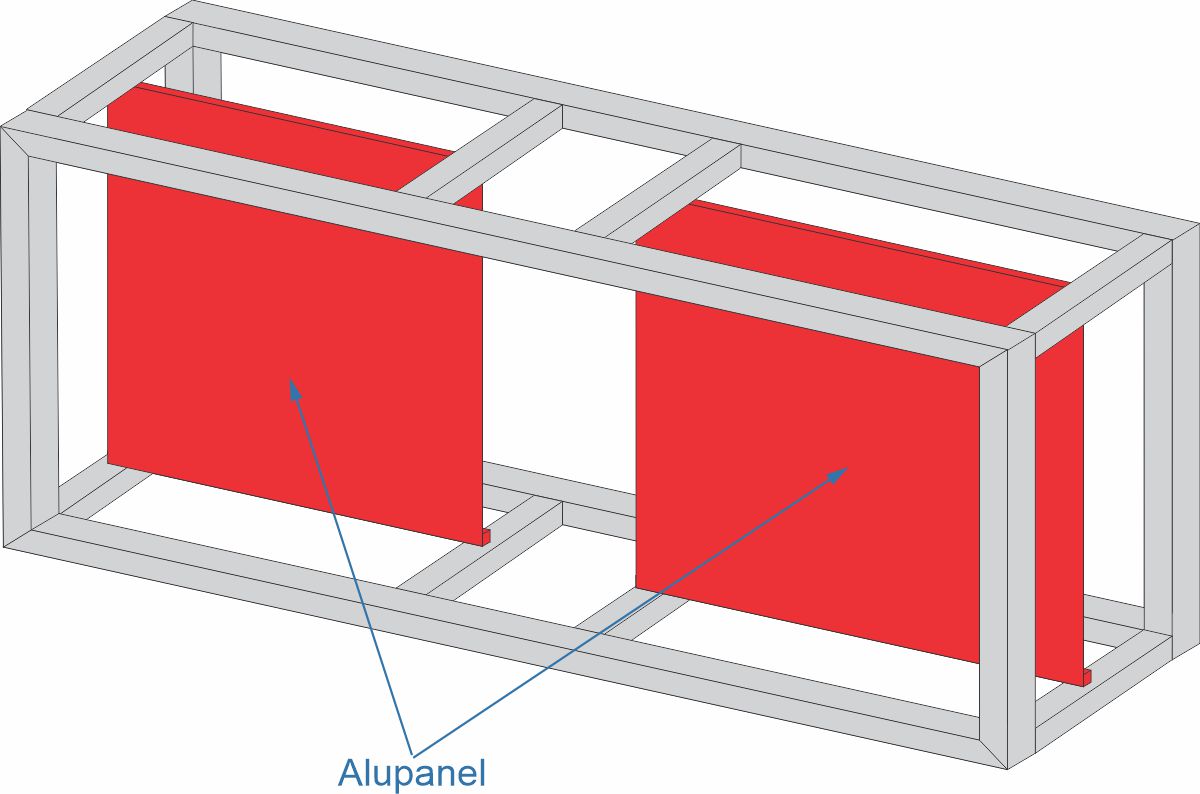

Step 3:

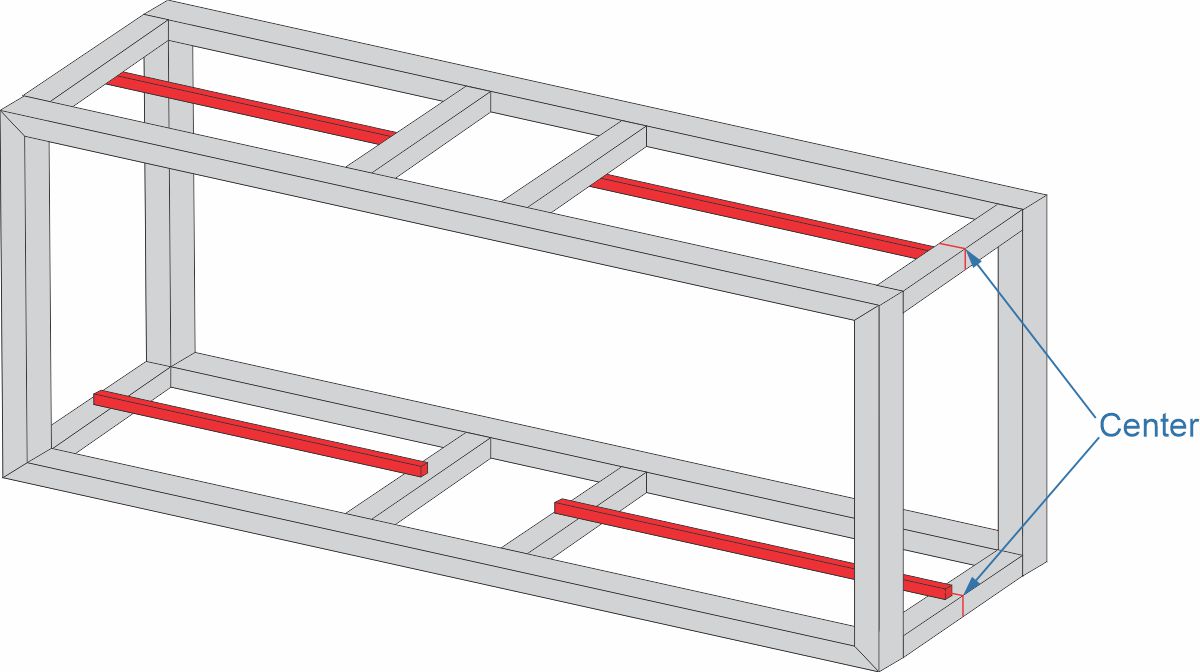

Next, proceed with installing the mounting brackets for the lighting components. Using 1×1” square tubing, weld the pieces between the center pole mounts and the outer edges of the frame. See Below:

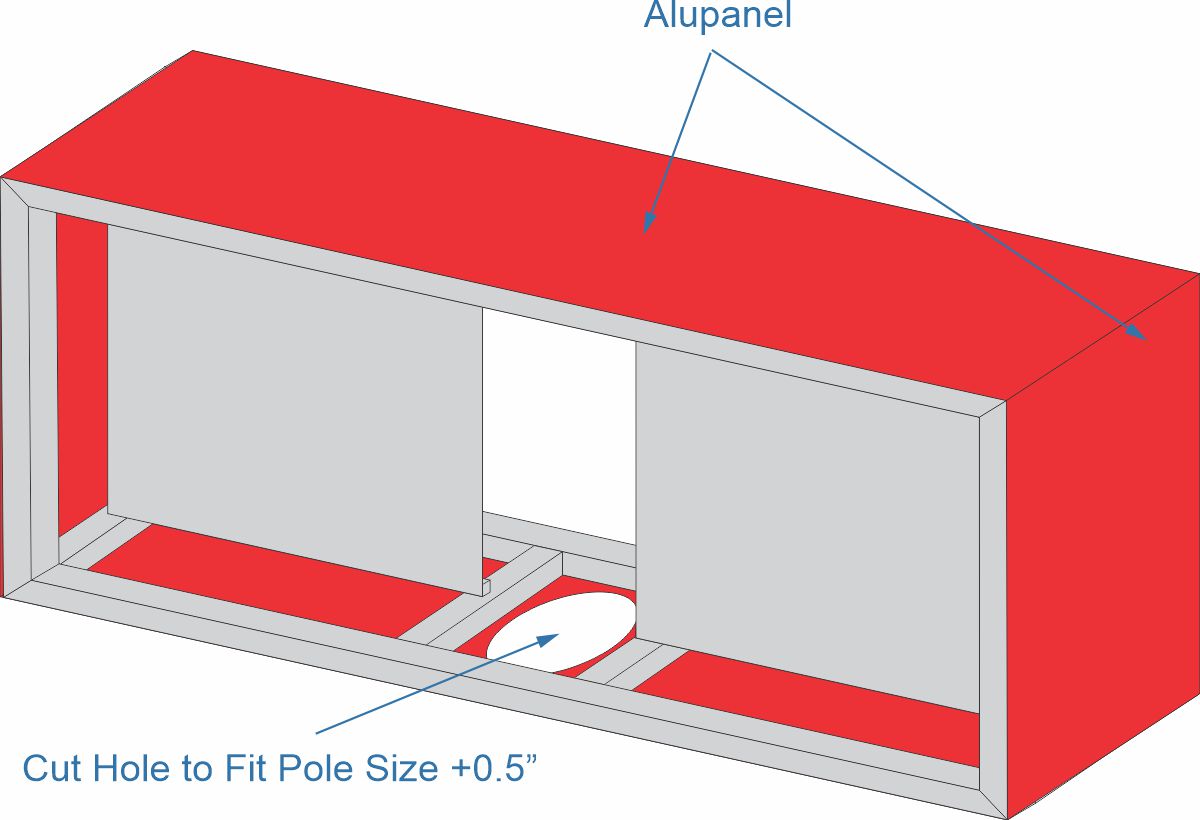

Step 4:

Cut the Alupanel (ACM) to the appropriate width and height to fit securely onto the 1×1” tubing previously installed. After cutting the sheets to the required dimensions, visit https://ezlayout.principalsloan.com/ to determine the optimal layout and the number of QwikMOD4 LEDs and power supplies needed for each side of the ACM. Once the LED layout is finalized, install the modules onto the cut ACM sheets. Finally, using self-tapping screws, securely mount the sheets onto the 1×1” tubing. See Below:

Step 5:

Using Alupanel (ACM) or aluminum sheeting in the approved color, cut pieces to cover each outer side of the frame. Ensure that the dimensions of each piece are accurately determined, taking care to achieve flush-fitting corners where the pieces meet. Attach with heavy duty double sided tape. See Below

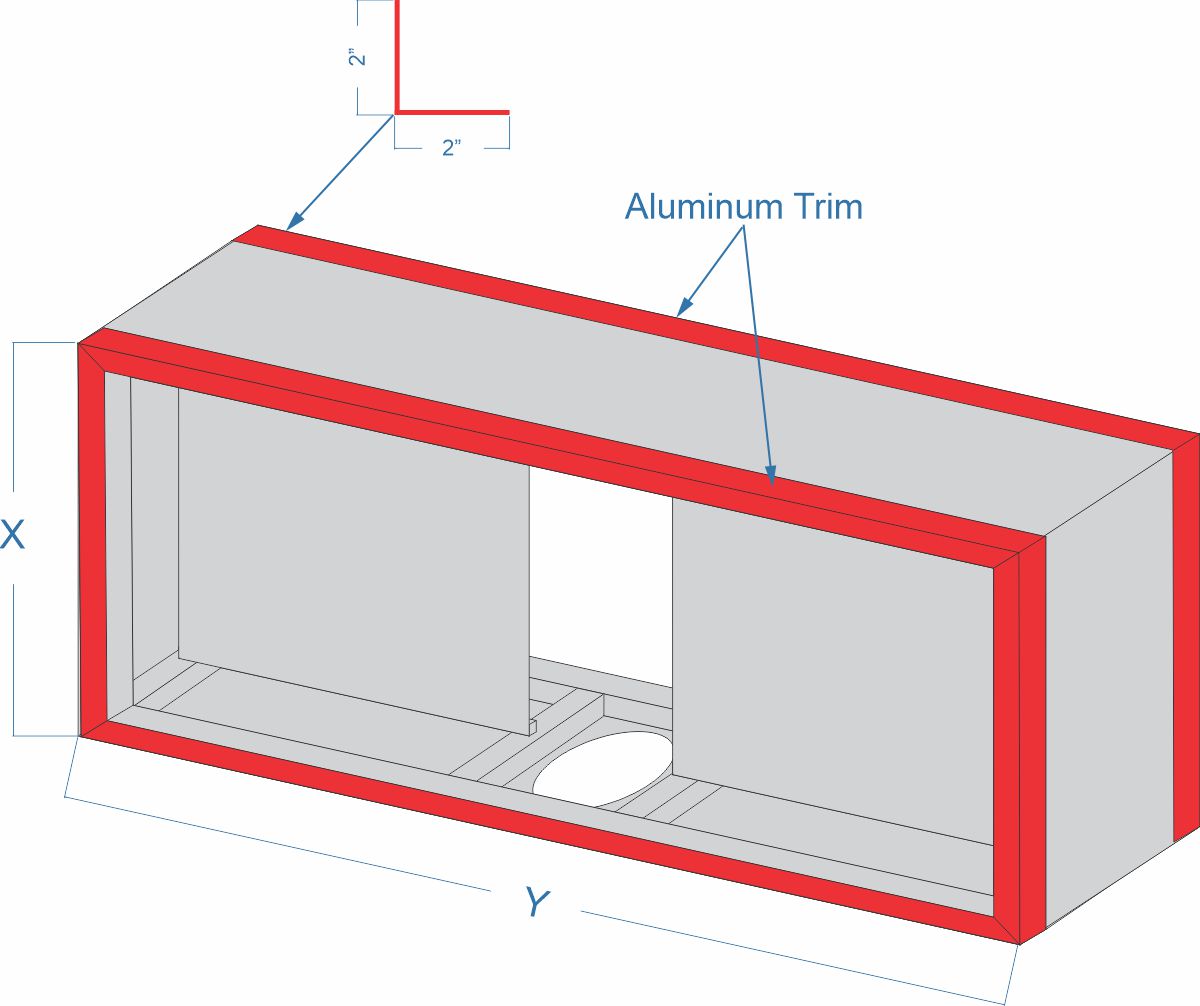

Step 6:

Take .040 Aluminum in the approved color to your local sheet metal shop (as of this writing, Timmons Sheet Metal in Bartlesville) to get trim made. General size is 2×2” but sometimes a larger size like 3×3” or 4×4” is also needed. You will need 4 of each Height (X) and 4 of each Length (Y). (Y) should have 90° cuts, and (X) should have 45° cuts on the front sides of each end. See Below:

installation:______________________________________________________

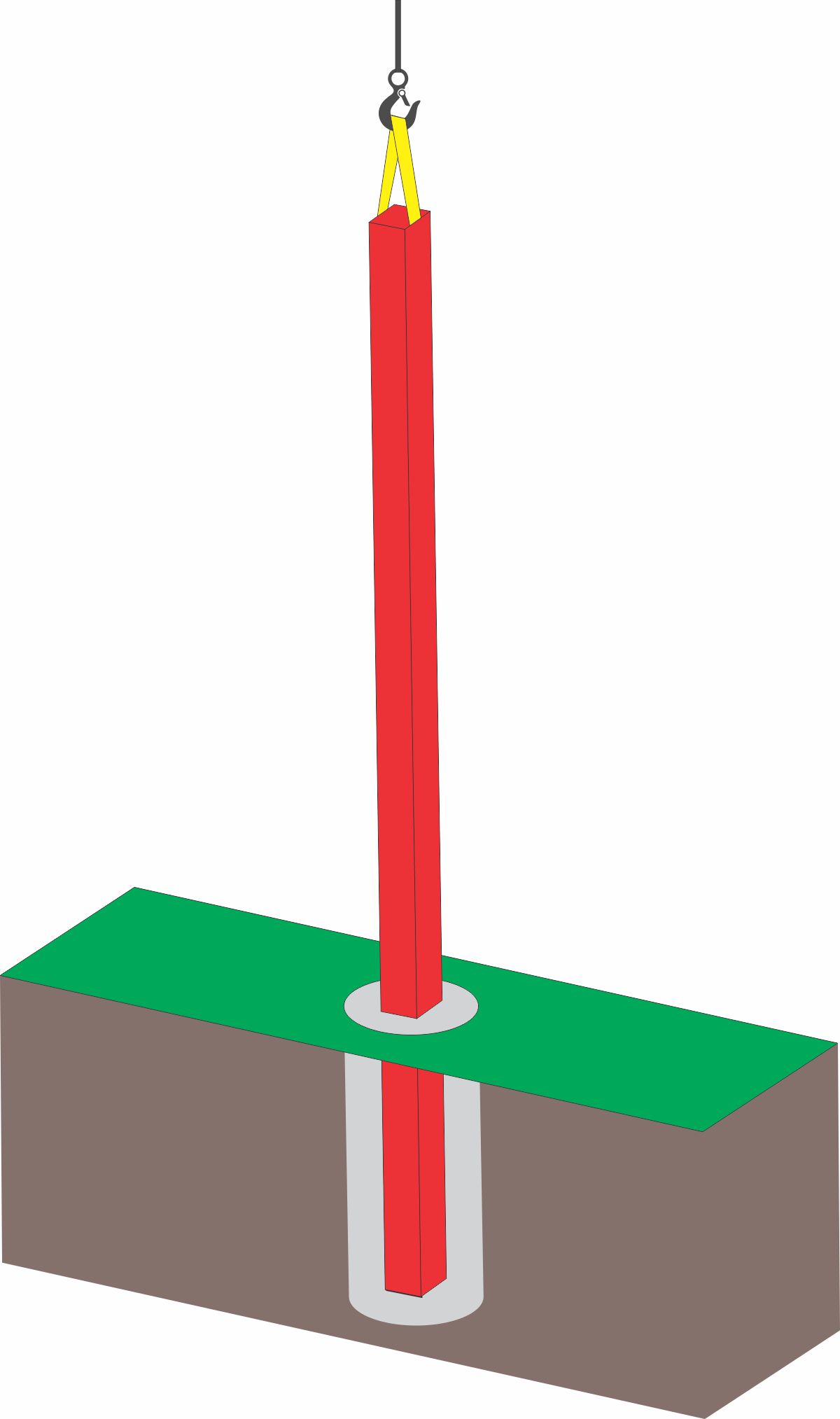

Step 1:

Schedule a utility locate with Okie811 at https://geoappv3.okie811.org/ui/dashboard. DO NOT proceed with digging until utilities have been properly located and marked. Hitting an underground utility can result in significant fines or, in the worst-case scenario, catastrophic consequences, including death.

The excavation will be scheduled and performed by a local contractor using an auger or excavator. Once the hole is prepared, we will lift the pole using a crane, place it in the hole, and ensure it is level. Typically, the hole will be 12-18” in diameter and 4-5 feet deep, though the size of the hole and pipe may vary based on the height and size of the sign.

We will then fill the hole with concrete, carefully checking to ensure the pole remains level on all sides throughout the process. Once the concrete is fully poured, the truck will remain connected to the pole to hold it in place until it is sufficiently secure, usually 1-2 hours, or occasionally overnight if necessary.

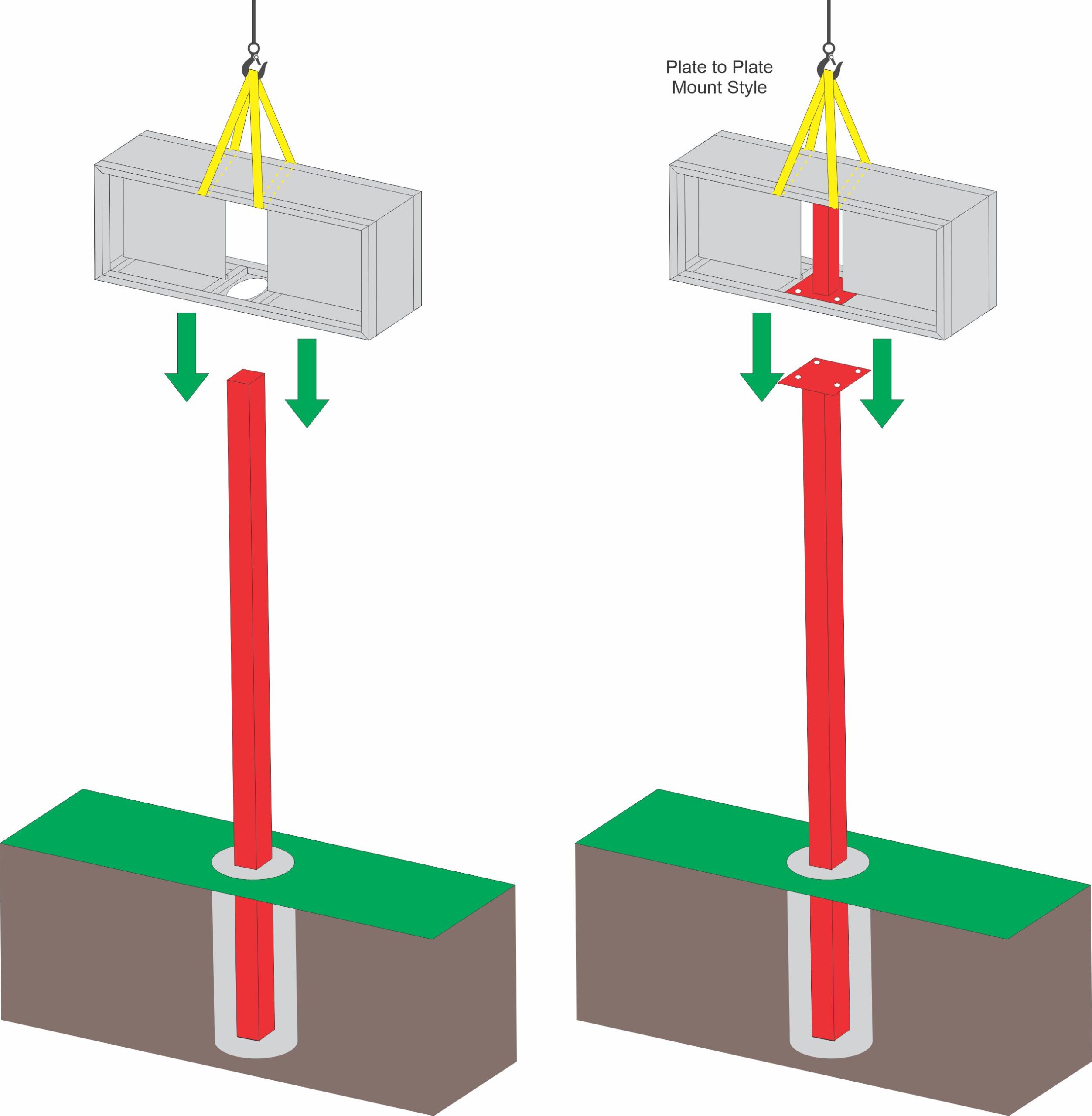

Step 2:

Once the concrete has cured and the pole is secure, use the crane to lift the sign and carefully lower it over the pole, guiding it through the pre-cut hole at the bottom.

Step 2B:

For plate-to-plate mounting, use the crane to lift the sign and gently lower it onto the pole, ensuring the plates are in direct contact. Secure the plates using four bolts. Insert the bolts, each accompanied by washers, upward from the underside through the pole’s plate. Apply a washer, lock washer, and nut on the upper interior of the sign to fasten securely.

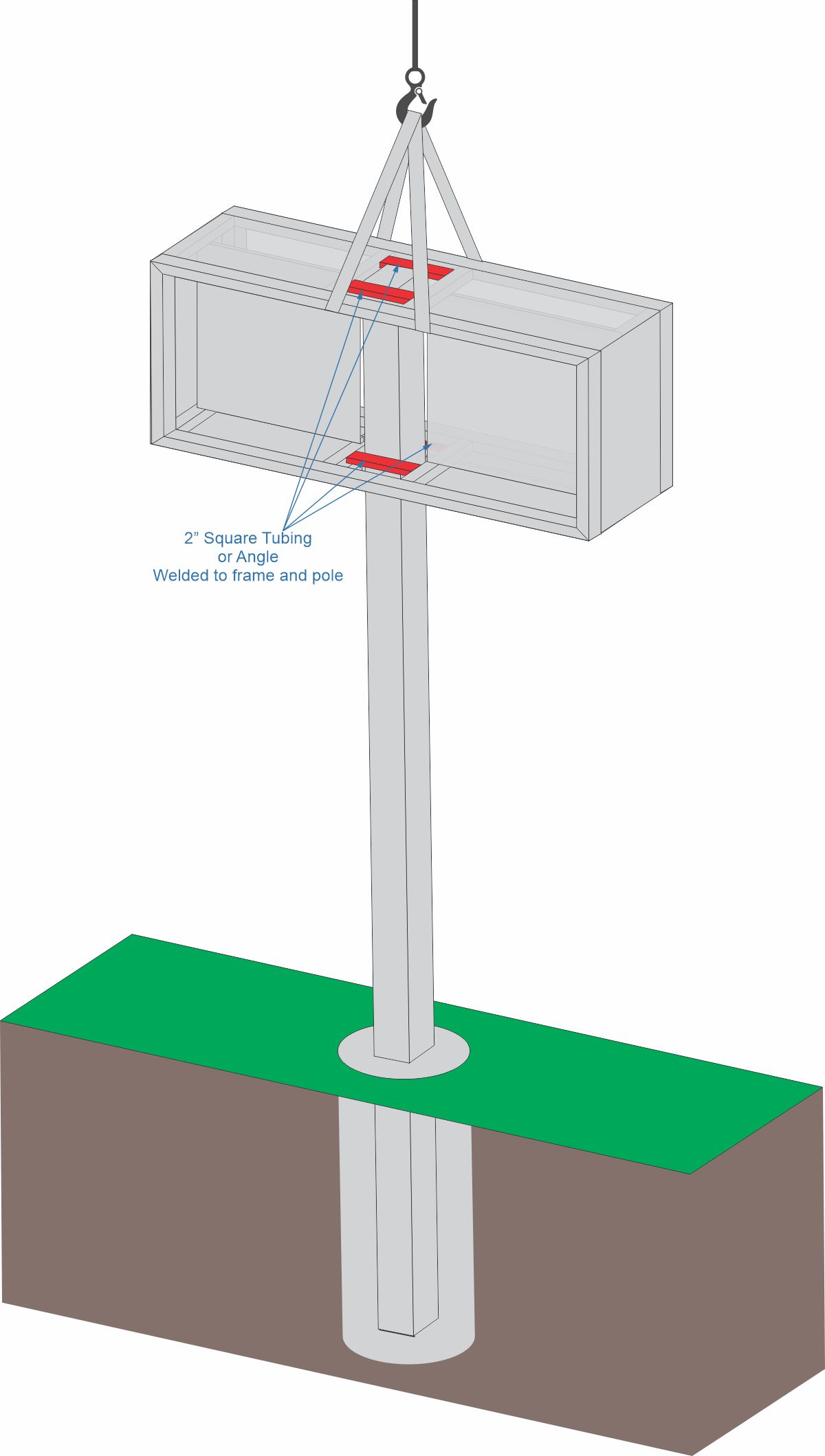

Step 3:

Secure the sign by welding two pieces of 2” square tubing or 2” angle to the top and bottom of the sign, connecting the pole and sign frame on each side. (Refer to the provided image.) Ensure the sign is level. A second technician should observe from ground level to confirm the sign is precisely perpendicular to the road.

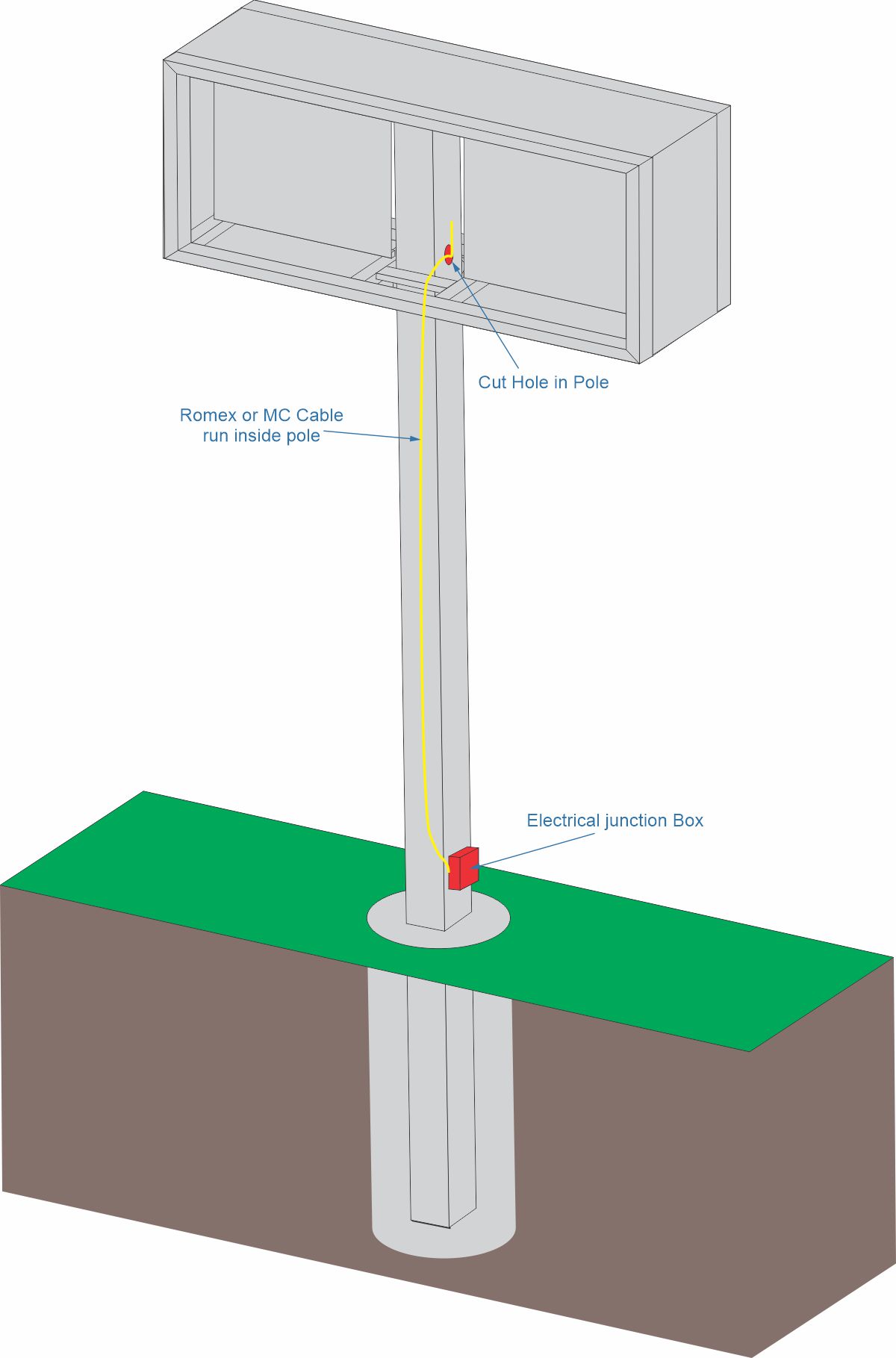

Step 4:

Once the sign is leveled, secured, and all welding is complete, disconnect it from the crane. Drill or cut a hole near the bottom of the pole inside the sign, large enough to route your Romex or MC cable to the pole’s base. Repeat this process near the ground, ensuring the hole is large enough to easily pull the wire through but small enough to be concealed by the electrical box. Once the holes are created, run the wiring from the top to the bottom hole. Connect the wire to the power supply inside the sign and test the connections using a generator at the base of the pole to confirm proper operation. Finally, take a photo of the sign’s lighting to verify that the wiring is functioning correctly. (If the external electrical wiring has already been installed by an electrician, make the necessary connections accordingly.)

Step 5

Install the sign faces. Remove the necessary trim and slide faces into frame. (Depending on size, you may use the crane and lifting bar if needed.) If sign is a flex face, remove all trim and attach faces using the flex face clamp system. See here (https://highwaymansigns.com/training/install-2/install-flex-face-installation/) for more info on flex faces. Once faces have been installed, installation is complete. Take photos and email them to info@highwaymansigns.com for our records.